| |||

Family Garden Trains, click on any link below: | |||

|  |  | |

|  | ||

|  | ||

|  | ||

|  | ||

Written by Paul D. Race for Family Garden Trains(tm)

Photos by Peter Wine for Media Moments

| |||

Family Garden Trains, click on any link below: | |||

|  |  | |

|  | ||

|  | ||

|  | ||

|  | ||

Written by Paul D. Race for Family Garden Trains(tm)

Photos by Peter Wine for Media Moments

Other People's Feedback and Other AdditionsDave Smith, long-time Big-Trains member describes his experience trying to cut the HDPE lumber:I'm trying out that new HDPE roadbed technique as designed by Bill Logan. Thus far all I've done is locate a supply of the stuff (no easy feat) and ripped it into the required pieces. A work of instruction to anyone trying this. I'm using an old Shop-Smith table saw. I took the supplier advice and used a carbide tipped blade with as few teeth as possible. This goes contrary to what I would have used (many teeth, smoother cut!). However, what you're trying to do is minimize friction and heat. So I begin cutting and I smell and see the plastic kind of melting. After 2 or 3 cuts the blade is warm and hardly cutting the plastic. All of a sudden in a brilliant revelation (a VERY rare occurrence for those who know me), I switched the saw blade speed to the lowest speed (you do that on a Shop-Smith by putting the belt on different pulleys). Well, lo 'n behold the saw started ripping through the HDPE like butter. The only other problem I had was the fence moving! So, my other recommendation is, check the fence after each 8' rip. My next step will be to try and see how the heck you lay this stuff out to form curves in "standard" LGB 1600 curved track (Bill crew seemed to lay the roadbed out free style for flex track. I don't use flex track).

|

|

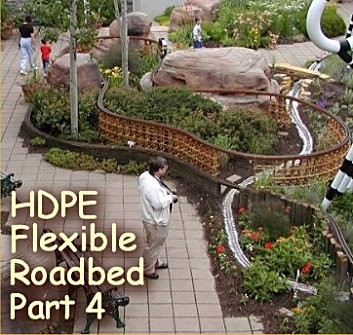

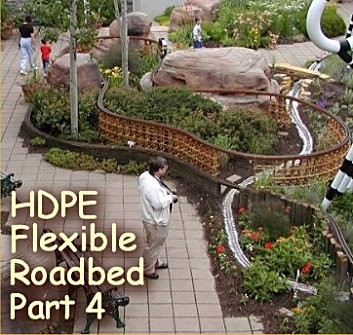

Peter Wine, garden railroad builder and producer of the

Holiday Garden Railroads videos says:

I haven't yet been able to find a supplier of [solid HDPD] plastic wood around the Dayton area. Trex does work if you're using moderate to wide curves, but I wouldn't advise using it for tight curves - it will break under enough stress. In 172' feet of roadbed in Eaton, I didn't have any breaks. (Of course, I also modified the project by using some 5/4 width planks instead of the 2x4 style, but we won't talk about that now.) I do like the method, and would use it again rather than cut 2x6's. The biggest advantage is that the roadbed comes out the same size as the track, and doesn't have the overhang that 2x6's do. In Franklin Park, where we put in some 800' of the stuff, I think there was about 10' of straight track . . . . The rest was all curves. About the difference between composite (Trex, etc.) and HDPE lumber, Bill adds: The HDPE lumber is the flexable component. Trex or treated lumber do not bend as much and do not yield as good a solution. Keep it simple - stick with HDPE. |

|

Bill Logan, answering a fellow's question about making the "ladder" framework wider to accommodate two tracks says: Wide ladders and off center post attachment defeat the design and will introduce unwanted torking (twisting of the raodbed and hence the track). Been there done that. Do not rely on the dirt for vertical support between posts. The dirt stabilizes the roadbed from horizontal movement and hides it from view. Wil Davis, responding to another question about using this method for double track, says: From what I saw, the way to do double track would be to make two and put an appropriate spacer in between to get the center-to-center spacing. If you simply made two and screwed them together they would be so close that the tie ends would touch. I would assemble the first one and one side plus center spacers of the second track. I would then attach this with the appropriate spacers to the first section and once the curve is formed, attach the remaining side. I hope this is clear. There may be a need to have some sort of horizontal support under the assembly due to the increased width. Turnouts should be no problem, they would just need special cut center spacers, but they could just be screwed to the existing single track at the appropriate point. |

|

Responding to another question about double tracks and about turnouts, Bill Logan added:

|

Where to Buy HDPE LumberSeveral people have written to say they had trouble getting this material in their "neck of the woods."The following companies offer HDPE or other "plastic" lumber, although a few of them also offer "comingled" or "composite" lumber (made from woodproducts mixed with plastics, of which Trex is the best known brand name).

A reader from Australia says that REPLAS, a supplier in Victoria, has useful products. (Thanks, Keith)! |

|

|

|

|

|

|

|

Note: Family Garden Trains?, Garden Train Store?, Big Christmas Trains?, BIG Indoor Trains?, and BIG Train Store? are trademarks of Breakthrough Communications (www.btcomm.com). All information, data, text, and illustrations on this web site are Copyright (c) 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007, 2008, 2009, 2010, 2011, 2012, 2013 by Paul D. Race. Reuse or republication without prior written permission is specifically

forbidden.

Family Garden Trains is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com.

For more information, please contact us

|  |